Materials

Balancing the Brands. vision with package compatibility can have a large impact on the materials used for your package. We offer a wide range of materials that can be used in-stock packages from plastic, PCR, glass, aluminum and bamboo as examples, and we are happy to consult and provide guidance on material selection & decoration based on your Brands needs.

Not sure what materials to use? Our engineering experts can help advise you here.

PP

Polypropylene

Its properties come in a wide range and its more heat resistant than PE. It is often white, but is also available in clarified grades with excellent contact clarity. PP is offered in a wide range of properties that enable it to be used for products with high impact requirements and long term dimensional stability needs, and has a high chemical resistance. PP is the third most widely produced commodity plastic (after PE) and it is often used in packaging and labeling. Ask us about PP PCR.

PE

Polyethylene

PE is one of the most widely produced plastics in the world. It is available in LLDPE (linear low-density polyethylene), LDPE (low density), MDPE (medium density) and HDPE (high density). From soft and flexible to hard and sturdy, the various grades of polyethylene offer a wide range of properties that can be utilized based on your package’s requirements. Ask us about PCR for blow molding.

PET

Polyethylene Terephthalate

PET is the most recycled material in the world, and features excellent clarity and chemical resistance. The material can be utilized in several processes such as injection molding, blow molding, injection blow molding (IBM), and injection stretch blow molding (ISBM). Ask us about PCR for blow molding.

PETG/PCTA/PCTG

Copolymers

These materials are amorphous copolymer thermoplastics with above average chemical resistances when compared to other amorphous materials such as ABS or PMMA. They have excellent physical properties for a wide variety of packaging types and offer superior clarity over clarified PP. Ask us about PCR for PETG/PCTA/PCTG.

PMMA

Poly Methyl Methacrylate

PMMA, also known as acrylic, is a transparent thermoplastic often used in form as a lightweight or shatter-resistant alternative to glass. It’s commonly used as an outer jar or outer bottle due to its high clarity. PMMA is also known as plastic glass. Ask us about PMMA.

Learn more about Poly Methyl Methacrylate (PMMA) or Acrylic.

AS/SAN

Acrylonitrile Styrene

AS/SAN, the predecessor of ABS, has a good combination of rigidity, strength, toughness and transparency. Ask us about AS/SAN.

ABS

Acrylonitrile Butadiene Styrene

ABS is an alloy type material that brings high gloss, impact resistance and good mold-ability due to its three main components. ABS decorates very easily in any of the many decoration process’s available. ABS plastic is recyclable, having strong impact resistance, heat and acid chemical resistance. Ask us about ABS.

ALUMINUM

Not only is aluminum strong at eliminating unwanted environmental factors, it is also flexible enough that it can take on whatever shape the primary package calls for, while giving products a luxurious look and feel. Ask us about Aluminum.

GLASS

Glass is a non-crystalline amorphous solid that is often transparent. Glass can be molded and decorated in statement-making ways, and offers excellent chemical resistance and barrier properties for packaging. Ask us about Glass.

BAMBOO/WOOD

Bamboo, and wood in general, is a natural and renewable material that can be used as a nice statement piece in your packaging. It can be made into different shapes according to your needs. Ask us about Bamboo and Wood.

PCR MATERIAL

PCR is an acronym for Post-Consumer Recycled content, which has become more and more sought after and is commonly misunderstood and associated with other forms of recycle. Ask us about PCR.

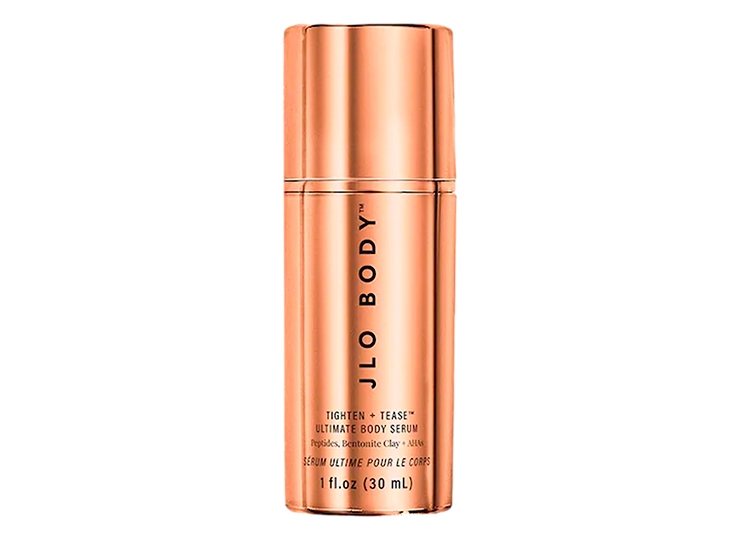

Decoration

An additional pivotal element in realizing your envisioned aesthetic is the impeccable finishing of your beauty packaging. APC Packaging presents a myriad of diverse options, meticulously tailored to cater to your preferences. Among these choices are in-mold coloring, inner and outer sprays, metallization, and an array of splendid spray finishes, such as pearl, matte, soft touch, glossy, and frosted.

IN-MOLD COLOR

Injection molding is a manufacturing process for producing parts by injecting heated and mixed material, such as glass and plastics, into a mold where it cools and hardens to the configuration of the cavity. This is the perfect time to have your desired color be a part of the material itself, rather than added later.

INNER/OUTER SPRAY

Spray coating a container offers the ability to create a customized color, design, texture, or all – on either glass or plastic. As the name suggests, in this process containers are sprayed to attain the desired effect — from a frosted look, a textured feel, a single custom color background for further design finishing, or in any conceivable design combination with multiple colors, fades or gradients.

METALIZING

This technique replicates the look of clean chrome on containers. The process involves heating a metallic material in a vacuum chamber until it starts to evaporate. The vaporized metal condenses on and bonds to the container, which is being rotated to help ensure uniform application. After the metalizing process is completed, a protective topcoat is applied to the container.

HEAT TRANSFER

This decorating technique is another way of applying silk screen. The ink is transferred to the part through pressure and a heated silicone roller or die. For multiple colors or labels with half-tones, heat transfer labels can be used which will provide color quality, registration and competitive pricing.

SILK SCREENING

Silk screening is the process in which ink is pressed through a photographically treated screen onto the surface. One color is applied at a time, with one screen for one color. The number of colors required determine how many passes are needed for silk screen printing. You can feel the texture of printed graphics on the decorated surface.

HOT/FOIL STAMPING

Hot stamping is a technique in which colored foil is applied to the surface through a combination of heat and pressure. Hot stamping produces a shiny and luxurious appearance on cosmetic tubes, bottles, jars, and other closures. Colored foils are often gold and silver, but brushed aluminum & opaque colors are also available, ideal for a signature design.

WATER TRANSFER

Hydro-graphics, also known as immersion printing, water transfer printing, water transfer imaging, hydro dipping or cubic printing, is a method of applying printed designs to three-dimensional surfaces. The hydrographic process can be used on metal, plastic, glass, hard woods, and various other materials.

OFFSET PRINTING

Offset printing uses printing plates to transfer ink onto the containers. This technique is more precise than silkscreen printing and is effective for multi colors (up to 8 colors) and halftone artwork. This process is available for tubes only. You will not feel the texture of printed graphics but there is one over-lapping color line on the tube.

LASER ETCHING

Laser etching is a process that creates marks on parts and products by melting their surface.

EMBOSSING & DEBOSSING

Embossing creates a raised image and debossing creates a recessed image. These techniques add branding value to the package by creating a unique logo design that consumers can touch and feel. This effect is created with a custom tool. LEARN MORE

Private Molds

Whether you are creating a completely new packaging solution or you just want to customize an existing mold, our private mold service allows you the freedom to create packaging for your unique requirements. A private mold can be created for an entirely new product or just a component of the packaging.

Our engineering team in our US headquarters works in conjunction with our engineering team in the factory to guide you every step of the say from technical and 3D drawings to suggestions about the best materials to use. APC Packaging also has capabilities in their headquarters to print samples using 3D printing technology. This ensures that the final product meets all of the brand’s requirements.

The difference between Custom and Private Molds is that the client owns everything from the design, drawings and even the tool. The design is completely unique and can only be used by the client.

Not able to find the packaging solution that you need? APC Packaging offers many more options including private molds.

Request a free consultation with one of our packaging experts.

For all other inquiries, please contact Purchasing, Human Resources, Logistics or Marketing.